FAQS

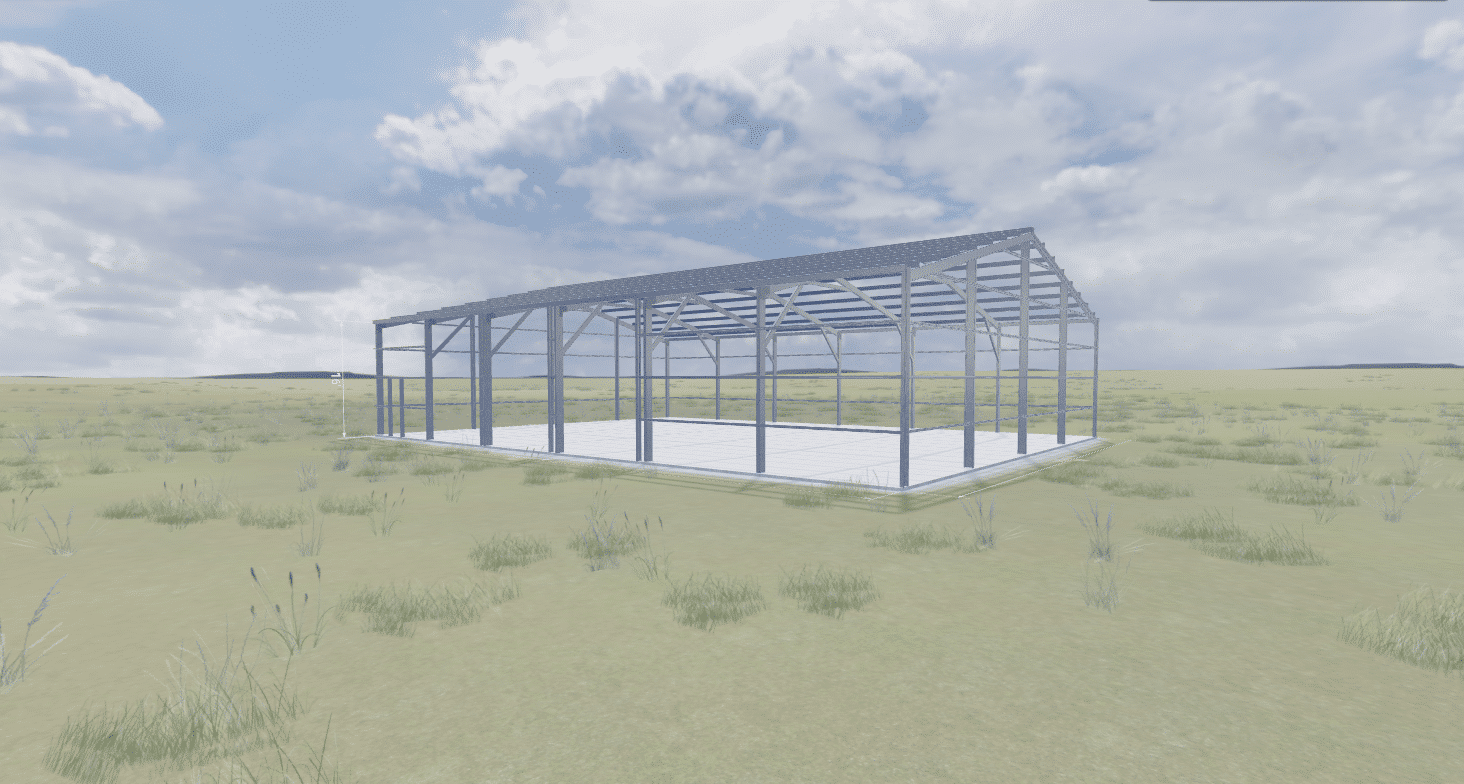

Cold Formed Buildings are constructed with roll formed components that are almost 100% weld-free, resulting in fewer manufacturing defects. In addition, job site fabrication is minimal resulting in a fresh, clean visual appearance. It is the most modern building system available in this day and age. Our cold formed buildings are made from a galvanized Cee & Zee purlin construction. These galvanized members protect against rust and have self healing properties.

The most common three are cold formed buildings, red-iron buildings and tube frame buildings. Each has their particular benefits though cold formed buildings far outweigh the other two systems for structures between 750 square feet and 20,000 square feet.

It’s critical to understand what you’re getting. For example, if you received a quote from us for $45,000 but got another quote for $39,000 from a different company, you might come to certain conclusions without knowing the real reason for the difference.

If that $39,000 quote came from a tube-frame company, it would be understandable. Tube-frame is warrantied up to a maximum of 20-years. Compare that to the cold-formed buildings’ 50-year warranty. Almost anyone would tell you that just $6,000 for another 30 years of guaranteed life from your building is worth it.

Our steel buildings are much more than just a space for storage, work or play. Our buildings on most properties, if permitted, raise the property value quite substantially. For example, if the total building project (concrete, installation, amenities, permitting and building cost) added up to $100,000, you can usually add ~2.5 times that value to the properties value. In the example above, you end up adding to the properties value by $250,000 at a cost of $100,000.

That’s a great question. Technically speaking, red iron buildings are old designs made from low-tech, outdated processes. Cold formed buildings are the most modern approach to a building system and provide the most value possible from every foot of steel used. As a side note, The name “red iron” started because manufacturers would apply a light, red, oxide coating to the members of the building to protect it from rusting during shipping. That coating is only for shipping the building and red iron is guaranteed to rust, hence the name.

Tube frame buildings are a low cost, short life span alternative to getting a building. Tube frame buildings usually only carry a 20-year warranty, if any at all. Cold formed buildings have a 50-year warranty. That’s pretty easy math.

In most cases you will need to pull a building permit to build a steel building, but not always. For example, some locations do not require a permit to build agricultural buildings. It’s always good to check with your local permitting office!

Most buildings use a 26 ga sheet metal panel that has a 25 year warranty on it. We offer a 26 ga sheet metal panel that has a 40 year warranty.

Viking Manufacturing’s buildings are all produced domestically with USA made mill-certified traceable steel, never outsourcing overseas material just to save a few dollars.

Many companies advertise steel and metal homes packages, when in fact they are offering wood framed buildings with steel sheet metal siding. Not all steel buildings will give you the cost savings or advantages when used as a home. Viking offers a high-quality cold formed building specifically designed for homes, barndominiums, warehouses and much more.

Our metal building kits can serve as the foundation for a massive variety of steel buildings. Our customers have designed and built residential homes, metal garages, carports, aircraft hangars, storage buildings, office buildings, barndominiums and more.

Barndominiums are affordable, energy-efficient, low maintenance metal buildings with residential living quarters inside. They can also be called “barndos” for short.

Viking Manufacturing is basically a client facing division of a larger parent manufacturing company which has over 75 years of steel building experience, over the last few years alone we have completed more than 1000 projects.

Prefab steel buildings are actually one of the most economical options for building a new building. They are designed and engineered for each specific project with very little wasted materials, which drastically cuts down on unnecessary building cost. They also go up fast, which saves money on labor. Using the standard designs you will also enjoy long time savings from the lack of maintenance.

To protect the confidentiality of our customers, we do not publish a list of customers or locations. However, you may call and speak to one of our consultants to see if there’s a building in your area. If so, we can contact that owner on your behalf to see if they are willing to show their building.

Because of the ease of erecting a steel building, there are many contractors across the country that can build your building. Depending on the size of your building project and location of your job site, Viking can help put you in contact with contractors.

Depending on the complexity of your building, the delivery timeline is relatively fast compared to the old style red iron buildings.

You should check the load at time of delivery and mark any damages you see on the BOL, and then notify us. If anything is wrong with your materials on delivery, we will make it right at no cost to you.

We offer rolled batt insulation with a stronger tear-resistant backing for your insulation needs. You can even do the insulation yourself if you’d like!

There actually aren’t any exterior bolts required for our buildings. All exterior screws that are required are manufactured to the highest quality and meant to last the life of the building. Any exterior screws are color matched and include a seal washer for long-lasting protection against the elements.

We always include state-certified, stamped, structural and foundation engineering documents with our buildings for an easy permitting process.

Still Have Questions?

We have a passion for unconventional solutions that bring your vision to life.